Kifco Water-Reels are an automatic form of portable irrigation which use one of four Drive Options to turn the Reel and retract the Gun Cart (Sprinkler) back to the machine where it automatically turns off. B-Series Water Reels can be equipped with either a Turbine, Bellows, Electric Motor or a Gas Engine Drive. Ag-Rain Water Reels can be equipped with either a Turbine or a Gas Engine Drive.

Bellows Drive

Kifco utilizes the highly efficient bellows drive mechanism in Models B110 and B140. The bellows drive is capable of retraction without consuming any pressure in the process. This allows 100% of the pressure provided at the machine to be available for irrigation rather than used or consumed by the drive mechanism. This is the preferred drive for machines that tend to operate at low pressure and flows (small diameter models). The bellows drive discharges and dissipates a small quantity of water used in the retraction.

Electric Motor Drive

The Kifco B-Series E100, E110 and E140 utilize the Electric Motor Drive option. These models can irrigate from almost any residential water source because of the simplicity of the electric drive and allowances for lower pressures and flows. The motor on the E100 is powered by a 110V, 200:1 ratio electric motor with a 15' water proof power cable. The motor on models E110 and E140 is powered by a 12V rechargeable battery (battery not included) with a run life of approximately 40 hours. This allows users to irrigate using a low quality water source without a booster pump.

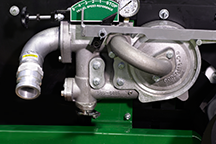

Turbine Drive

All Ag-Rain and B-Series Water Reels with tube diameter of 1.8” and larger utilize the Turbine Drive. The Kifco turbines are the most efficient turbine drive in the industry (10 PSI or less pressure used in the turbine) and are a reliable, efficient and highly adjustable drive option. Kifco impellers are precision machined from aluminum or composite material for longevity and resistance to corrosion.

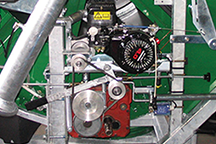

Gas Engine Drive

The gas engine drive option is primarily used for applications where solids (animal waste or fibrous materials) are present in the water. It is also used in applications where the customer requires high speed irrigation or has limited water pressure and cannot afford pressure loss in the turbine.